Factors affecting pump minimum flow

Experience engineers aware that Centrifugal pump will experience to cavitations when flow rate reach it minimum allowable flow. What are factors affecting pump minimum flow other than internal circulation?

There are five known factors will affect the minimum flow rate of a pump.

a) Fluid temperature rise

b) Minimum stable flow

c) Internal recirculation

d) Thrust capacity

Fluid temperature rise

As fluid enters pump suction chamber, pump impeller will spin the fluid and energy from shaft / impeller is transferred into fluid. However, there are mechanical losses within the pump in the energy transferring process. The mechanical losses will be transformed into acoustic energy (e.g. noise) and thermal energy (e.g. fluid temperature rise). Acoustic energy may transfer to fluid, pump casing and piping and it is further emitted to atmosphere as noise. Similarly thermal energy will also transfer to fluid, pump casing and piping. However, pumping process is a rather “fast” action and in general there is “insufficient time” for heat transfer from fluid to pump casing and piping. Thus, majority of the thermal energy will stay in the fluid and eventually cause fluid temperature rise (and/or liquid flashing). Reduce fluid passing pump results less heat “carrier” and higher temperature rises and high potential of liquid flashing. Thus a minimum flow can be established from fluid temperature rise.

A process engineer may needs to establish minimum flow of a pump from temperature rise perspective. The principle is rather simple where

Energy loss to fluid = fluid thermal heat gain

Above has considered acoustic energy is zero.

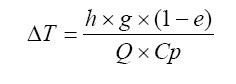

Fluid temperature rise,

h = pump head

g = gravity acceleration

e = pump shaft efficiency

Q = pump flow

Cp = fluid specific heat

Minimum system stable flow

Sometime a pumping system may shows two stable flows at certain pump head. As a result, it ”hunts“ or ”shuttles“ between these two flows and potentially damage the pump and other equipment within the pumping system. For example, gas trapped in the discharge line pocket. Trapped gas will reduce liquid flow path and increase line pressure drop. Pump head increase push trapped gas towards downward piping. As trapped gas move into the downward piping, liquid flow path increases and reduce the pump head. Trapped gas will form smaller bubble due to fluid turbulence and it will rise in the downward piping and finally back to the high pocket again. Similar cycle occurs again and pump oscillate in two flows. A process engineer shall always piping system to avoid pump operate in the oscillation region.

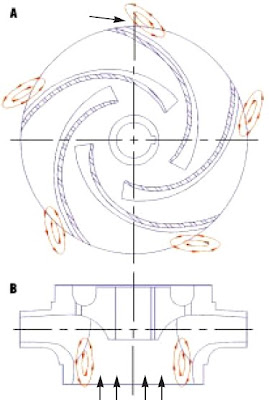

Internal recirculation

As flow rate decreases in the pump chamber, flow reversal will occur at the pump suction and discharge vanes. Recirculation vortex will form at both ends and potentially damage pump. Thermal heat gain within vortex will further increase pump fluid temperature and potential flashing occurs.

Axial thrust load

Axial thrust loadAxial thrust in a pump increases rapidly as flows are reduced and head increased. A minimum flow needs to be maintained so the thrust developed by the pump does not impair bearing life.

Minimum flow protection strategies

There are number ways to implement minimum flow protection strategy for centrifugal pump. Typically they are:

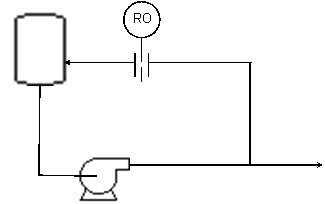

(i) A restriction orifice on pump discharge recycle line

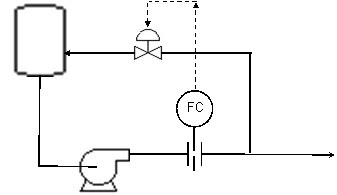

(ii) A flow meter on pump discharge with control valve on recycle line

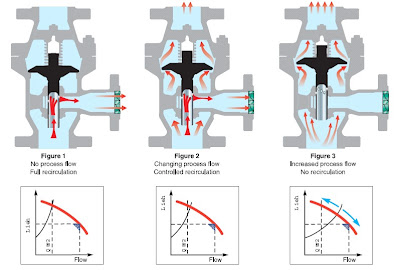

(iii) Use Automatic Recirculation Valves (ARC) valve

(iv) Flow-Delta P and flow meter on pump discharge with control valve on recycle line

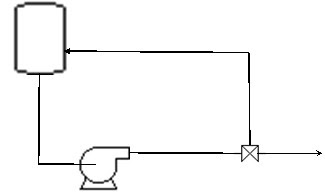

Fig. 1 restriction orifice on pump discharge recycle line

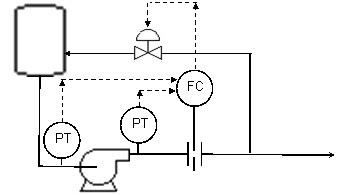

Fig. 1 restriction orifice on pump discharge recycle line Fig. 2 Flow meter on pump discharge with control valve on recycle line

Fig. 2 Flow meter on pump discharge with control valve on recycle line Fig. 3 Automatic Recirculation Valves (ARC) valve

Fig. 3 Automatic Recirculation Valves (ARC) valve Fig. 4 Flow-Delta P and flow meter on pump discharge with control valve on recycle

Fig. 4 Flow-Delta P and flow meter on pump discharge with control valve on recycleThe following list out the advantages and disadvantages for above four options

Restriction orifices

- Simple installation

- Maintenance free

- Large pump

- Waste energy all time

- Limit maximum pump output.

Orifice plate in the discharge line

- No continuous recycle thus energy saving

- consumes energy and also slightly reduces pump capacity.

- Using orifice plate to measure flow will results high inaccuracy e.g. minimum flow is 40% of maximum flow, 7% of the set point may be expected.

ARC valve

- Simple & effective

- Lack of flexibility.

- Unstable operation

- expensive

Sketches below show outlook and operation of an ARC valve

- Similar to orifice plate option

- Good option for load sharing of pumps in parallel installation

Restriction orifice option is the most common option adopted in many applications with LOW capacity system and a process engineer is advisable to consider this option. However, for HIGH system and appreciable energy losses is possible, a process engineer is advised to consider flow orifice with control valve option. ARC valve may be a good option to consider if process engineer is well aware of the fluid characteristics and familiar with the operation & dynamic of ARC valve. For very high capacity system and load sharing may be expected, process engineer may consider Flow-Delta P option.

Reference :

S, Mirsky, << Pump Control Strategies Benefits from Compressor Know-How >>, Hydrocarbon Processing, Feb 2005

Walter Driedger, <<CONTROLLING CENTRIFUGAL PUMPS>>, May 2000

TYCO, <<YARWAY 9100 Series ARC Valve For Centrifugal Pump Protection>>,

JoeWong